A Guide to the A-SUB T-shirt Transfer Paper

Introduction

In the printing world, you’ve likely come across the use of sublimation paper. That’s why printers employ this particular type of paper in transferring designs to garments via heat application.

Yet, you should be aware that sublimation paper has limitations in transfer printing.

The sublimation process does not work with 100 percent cotton composition fabrics. Why? Because sublimation ink only binds with polyester or poly-blend materials.

A key benefit of sublimation is it adds no extra layer to a fabric. However, this effect will pose a when working with black or dark-colored materials. You’ll have to print on white or light-colored clothes for your designs to be visible.

As a result of these drawbacks with sublimation paper, A-SUB developed the t-shirt transfer paper. Let’s examine this particular paper and its best uses in transfer printing.

What is T-shirt Transfer Paper?

The t-shirt transfer paper is now widely popular in thermal transfer printing. But what’s the deal with this unique paper? And how can you use it?

Structure

Primarily, the t-shirt transfer has a composition of the base paper, ink absorption layer, and polypropylene (PP) film.

The base paper, or layer, serves as the foundation of the printing paper. It adds stability to the overall structure of the transfer paper.

The printed designs appear on the paper with the help of the ink absorption layer. This layer holds the printing ink before transferring the design to your fabric.

The PP film is a transparent layer on the paper that serves as the glue layer. This film allows the design to transfer and stick to the fabric properly.

Work Principle

So, how does the t-shirt transfer paper work?

The ink absorption layer receives ink without fading, thereby holding the design image. Then, the glue layer facilitates the transfer and attachment of the ink absorption layer to the selected material.

Application on Different Materials

Majorly, you can use the t-shirt transfer paper on 100 percent cotton fabrics. This is because pure (or 100 percent) cotton materials do not absorb or lock ink.

So, the ink absorption layer receives the ink during the transfer printing process. This ink absorption layer is attached to the base paper layer.

The PP film covering the ink absorption layer adheres the design to the clothing material. Consequently, it becomes harder to wash off the transferred design easily.

In addition, you can apply t-shirt transfer paper with clothing materials having synthetic fibers. This list includes

However, the fabric must have more than 30 percent cotton in the fabric contents.

Ink

The type of ink that the t-shirt paper uses is pigment ink. A pigment-based ink employs solid particles of pigment powder suspended in ink to transfer color.

Unlike dye ink, pigment ink has the advantages of longer-lasting prints and producing stable and vivid colors. Also, it is resistant to fading under sunlight and does not wet or smudge easily.

Classification

Unlike sublimation paper, you can apply t-shirt transfer paper to light and dark fabrics.

We have two types of t-shirt paper; light and dark transfer paper. So let’s check them one after the other.

Dark Paper

Dark t-shirt transfer paper finds application on dark-colored fabrics. Dark fabrics require a special transfer paper with a white background that transfers with the ink. Also, this white background blocks out the color of the substrate from coming through with the ink.

Thus, the resulting images appear in block form or with white edges. These white areas undergo slicing before the transfer. Else they will appear on the fabric.

Also, you can apply dark t-shirt transfer paper for printing on light cotton clothes.

Light Paper

As the name implies, the light t-shirt paper works well on light-colored cotton fabrics.

Generally, the transfer paper produces vibrant and authentic images on white and light-colored clothes. The printing ink is translucent and is usually not visible except on white or light-colored background.

Equipment

Either an electric iron or heat press machine will be effective on a t-shirt transfer paper. You need to follow the manufacturer’s instructions to get the desired result.

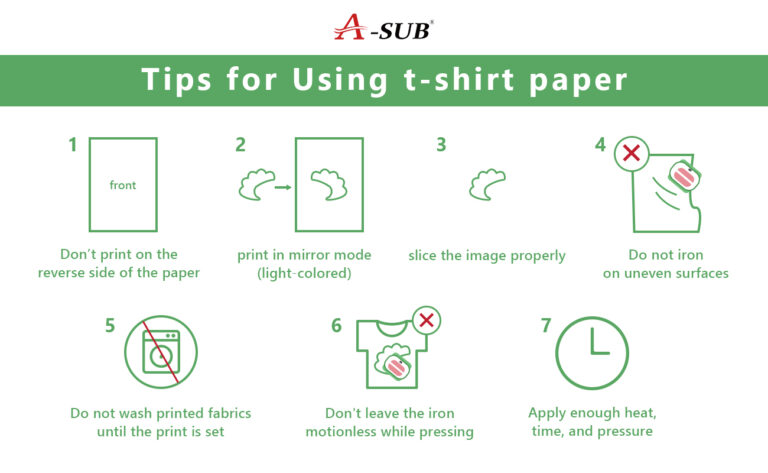

Tips for Using T-shirt Transfer Paper

-

Do not print on the reverse side of the paper.

A fundamental tip is to print out your design on the right side of the paper. Thus, you get the best results in thermal transfer printing

Manufacturers designate this part with slashes or semi-visible patterns. So, before laying your paper in the printer, take time to apply it right in the printer tray.

-

For light-colored printing, always print in mirror mode

You’ll need to use this technique when printing on light-colored fabrics. It’s essential if you have text in your designs.

So, when printing on a light background, reverse the image in your design software before printing on paper. As a result, the pictures and text will appear readable and not the other way round.

-

Remember to slice the image properly

You cut off the excess background around the design image when you slice an image. This technique makes sure your design is visible without any distracting white edges.

If you slice your design image unevenly, you get extra and unneeded fabric transfer paper on the garment. This excess paper ultimately reduces the aesthetic effect of your design.

-

Do not iron on uneven surfaces

You may decide to use an electric iron to apply heat to the transfer paper. In this case, place your fabric on a completely flat surface before ironing.

Also, do not use an ironing surface with excess padding. If you iron on uneven or padded surfaces, parts or all of the design images will not adhere to the fabric of transfer paper.

-

Do not wash printed fabrics until the print is set

A vital product guideline when using thermal transfer paper is to allow the printed material’s design to be set for at least 24 hours. After this period, you can carry out the laundering of the fabric.

However, the design image may smear or fade prematurely if you wash your fabric immediately after printing. Also, wash your garments inside-out to avoid rubbing the printed design on other materials.

-

Don’t leave the iron motionless while pressing

A key fixture of steam irons is the indentations or holes in the bottom of the iron design. These features allow steam to pass from the iron to the fabric.

But they might pose a problem in transfer printing because the iron will not apply pressure evenly across the paper. So, when using heat with a steam iron, always keep the iron moving for optimum results. Also, switch off the steam effect before ironing.

-

Apply enough heat, time, and pressure on the iron during the heat press

The three critical factors determining a good transfer printing process are heat, time, and pressure.

Before ironing on the transfer paper, set the iron to the hottest setting for the process to work. Also, the heat application process should last an average of 15 to 25 seconds. And apply sufficient pressure around all areas of the transfer paper for the proper effect.

Conclusion

The t-shirt transfer paper offers much more than sublimation paper in transfer printing. You can work on almost any kind of fabric, including pure cotton. Also, you can choose to print on either light or dark materials.

With all these fantastic qualities, t-shirt transfer paper is widely popular in thermal printing.

Even if you do everything right when performing thermal transfer printing, it won’t matter if you’re using low-quality paper.

So, go for A-SUB T-shirt Transfer Paper. At A-SUB, we delight in providing excellent service for our distributors.

Contact us and become a partner with excellence today.

2 comments